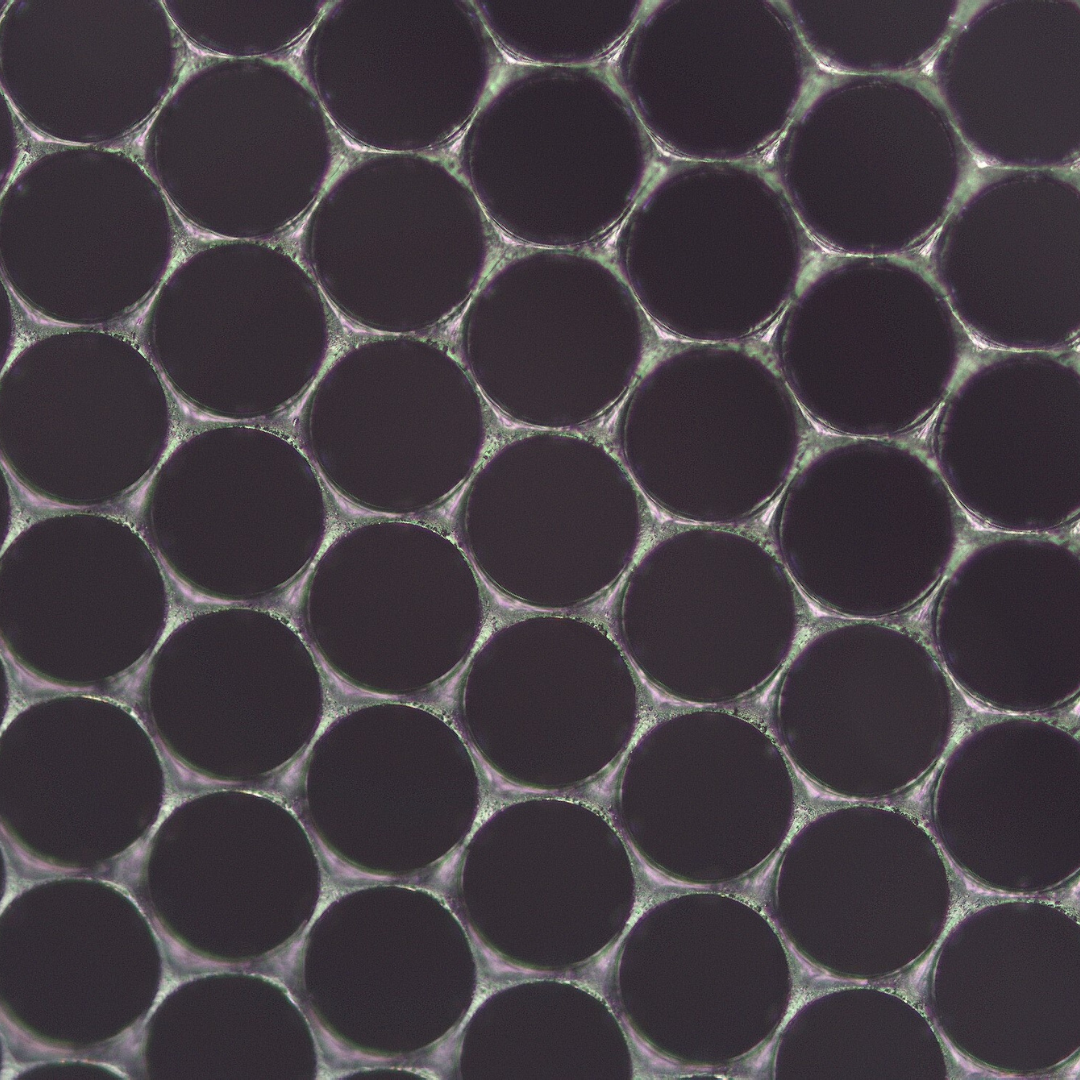

Micropore Filtration

resources

Design guide, Micropore Calculator

APPLICATIONS

Applications of micropore filters

CONTACT

Contact us to get started

Customizable Mass-Produced Plastic Micropore Filters:

- High-precision pore shape and diameter for extremely efficient monodisperse separation

- Wide range of pore diameter, pore spacing, and film thickness

- Possible pore shapes include cylindrical, conical, nozzle, and more

- Filters can be monolithically molded into more complex plastic parts

- Available material properties include resistance to solvents and non-specific binding, optical clarity, ultra-low background-fluorescence, and more

- Manufacturing takes place in an ISO-7 clean environment

- Additional treatments (plasma, surface coating, and more) and packaging options available

- Mass producible in-house to achieve very low per-piece pricing

Micropore filters play a crucial role in various filtration applications by effectively removing contaminants, microorganisms, or particles. This design guide provides key details about micropore filter design, including critical features such as pore shape, size, spacing, profile, thickness, and materials.

.png?width=1080&height=1080&name=micropore%20filter%20guide%20preview%20(1).png)

.png?width=1080&name=micropore%20filter%20guide%20preview%20(8).png)

Micropore Filter Calculator

Are you working on a specific filtration application? You can use this micropore filter calculator to determine pore coverage percentage, as well as the manufacturabiity of the desired design.

Start by entering your desired pore diameter based on what you're filtering. Then, figure out how closely spaced you want the wells and the overall thickness of the filter. Once you're done, you can click below to request a quote and share any other information.

Our proprietary process yields:

- Very dense pores for maximum pore area

- Material options that include low extractables and leachables

- Monodisperse pore size with a low-cost mass producible manufacturing method

- Monolithic direct molding into more complex plastic parts

.png?width=152&height=65&name=a%20ZEON%20company%20(3).png)

-1.png?width=152&height=65&name=a%20ZEON%20company%20(4)-1.png)