%20(1).png?width=4032&height=3024&name=image%20(76)%20(1).png)

Custom Microplates

Fully-customizable microplates across a broad catalog of applications

Microwell plates in 96-well and 384-well formats have been a staple of lab automation for decades. Uniform standards in well placement and depth facilitate the use of automation tools in laboratory processes, from multi-channel pipettors to liquid handling robots.

Edge can generate these features on microplates with industry-standard footprint. These plates slot seamlessly into your existing processes. They are ready to work on day one with your plate readers, thermocyclers, liquid handling systems, scanners, and microscopes.

In-house manufacturing

Most of our custom microplates consist of a custom molded bottomless well layer bonded to a featured bottom film or plate. All manufacturing occurs in-house, including two forms of thermoplastic molding as well as several different lamination methods. You can choose any number and configuration of wells, as well as many different sorts of microfeatures, including single-cell arrays, microchannels, and more.

.png?width=1200&height=1200&name=plate%20image%20(1).png)

Learn more about Edge’s microplate offerings in our detailed design guide, which includes information on:

- Options for number of wells and layout

- Material choices, including PMMA, polystyrene, and COP

- Lamination & assembly methods, including laser welding and thermal bonding

- Optional surface treatments, coatings, and other secondary operations

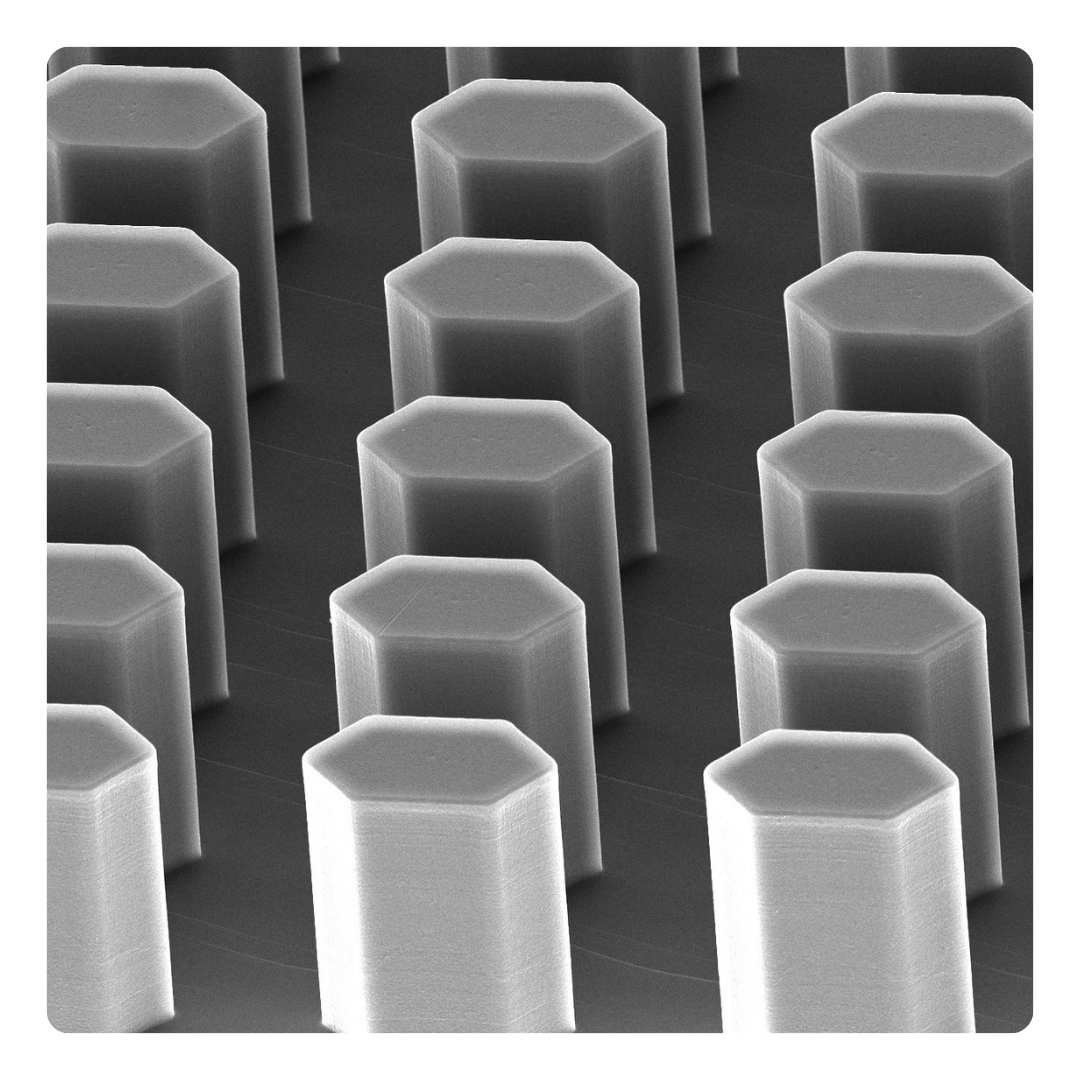

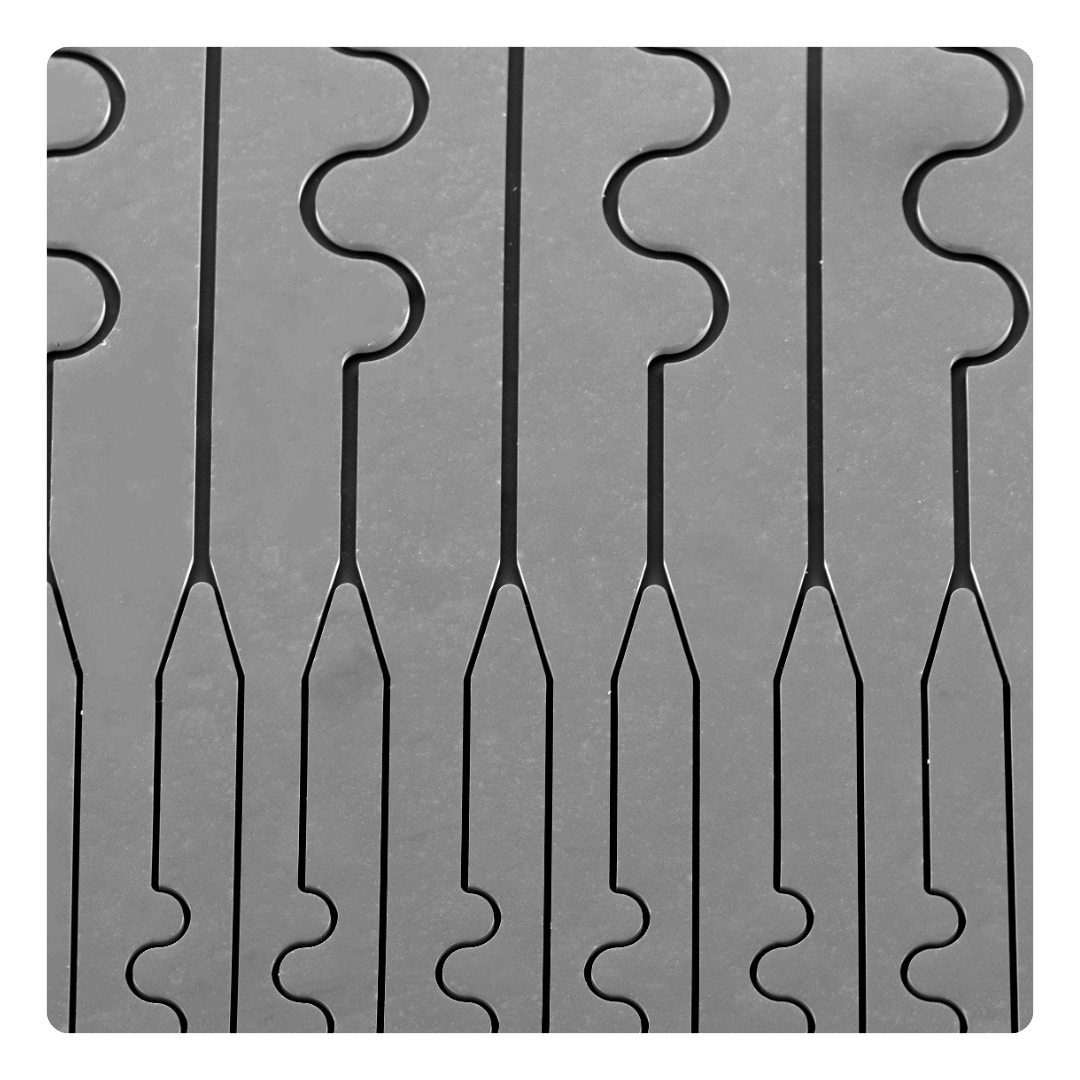

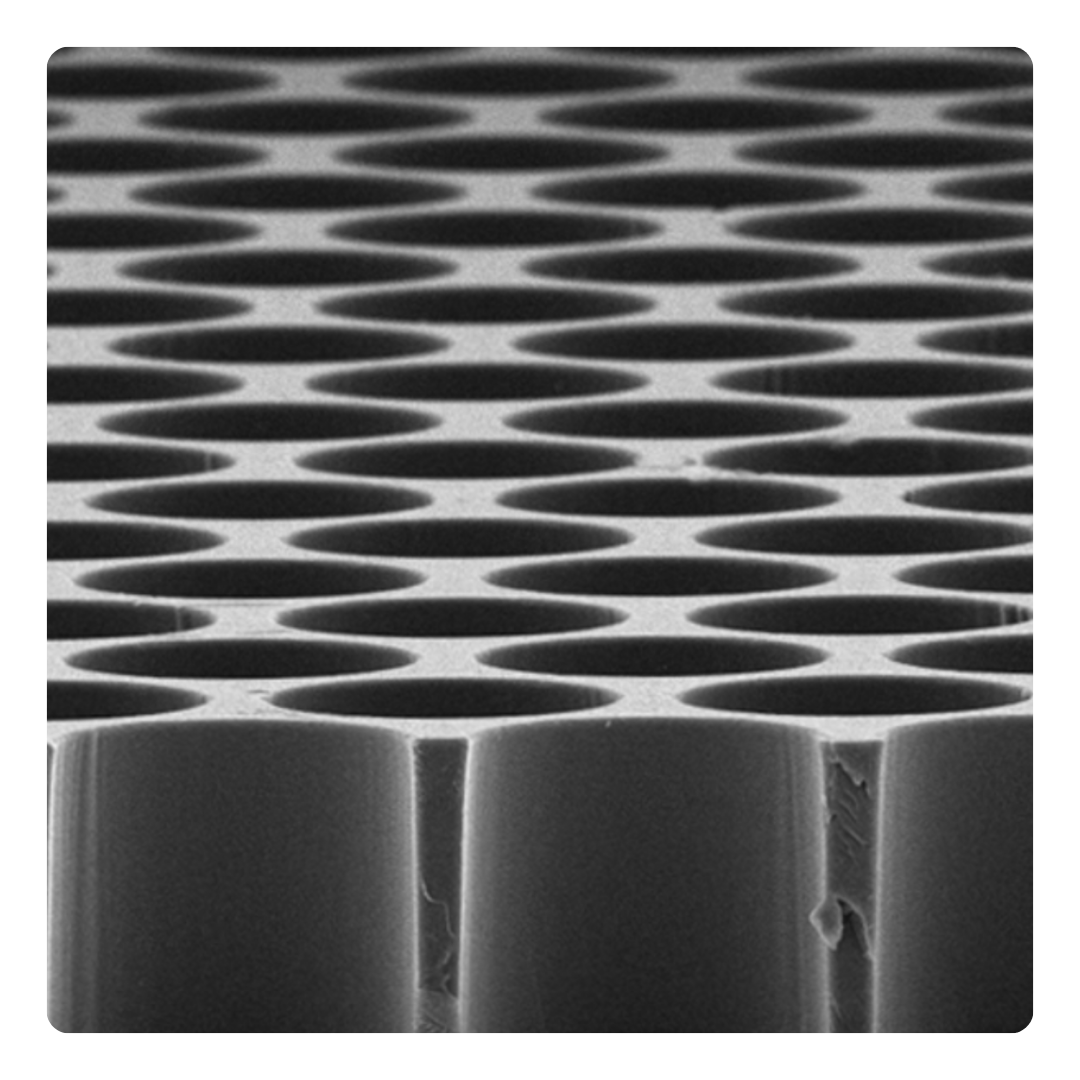

Customizable well features

The bottoms of each well are customizable with any microfeatures required, including microwells, microposts, micrpores, and channels that connect adjacent wells.

CONTACT US

Questions? Drop us a line, and our team will get back to you within one business day.

.png?width=152&height=65&name=a%20ZEON%20company%20(3).png)

-1.png?width=152&height=65&name=a%20ZEON%20company%20(4)-1.png)