Assembly Services

As a plastic consumables manufacturer, Edge takes a pragmatic approach to assembly services so our customers can confidently bring products to market.

Assembly Services

We provide assembly services to fit a range of needs, from custom solutions to traditional options.

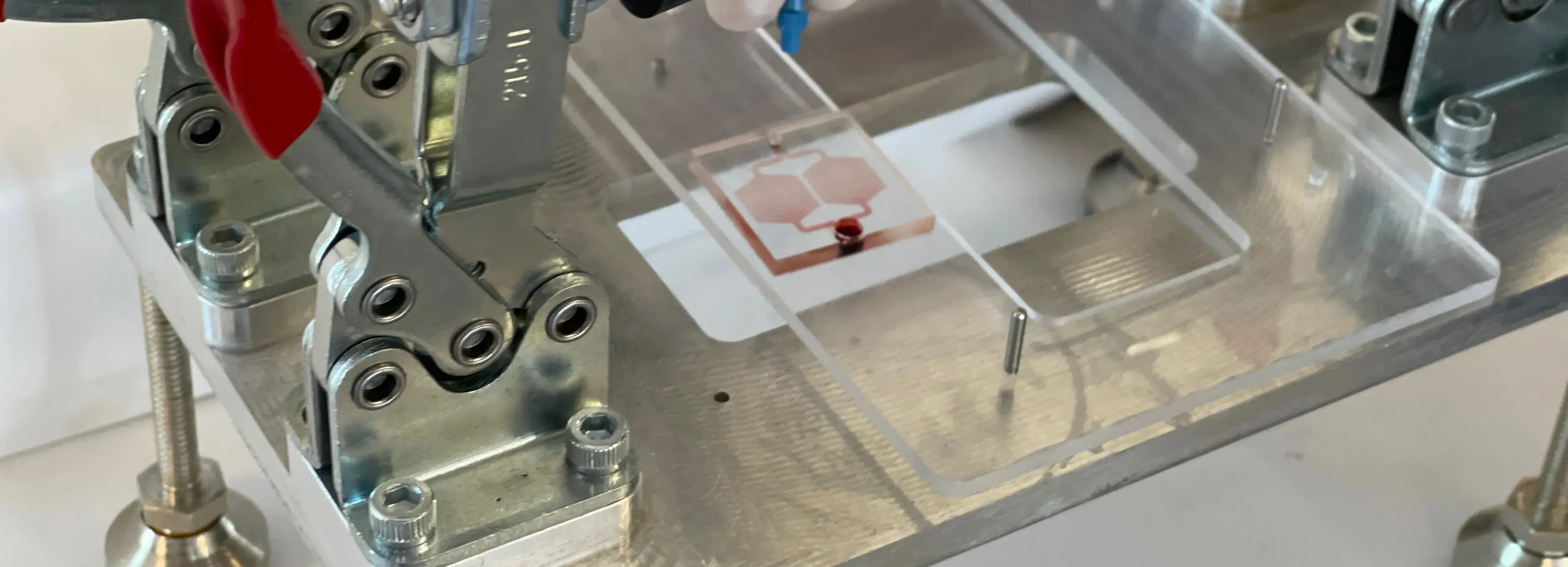

Direct thermal bonding/low deformation component assembly

Adhesive dispensing

Heat stake and heat sealing

Mechanical Component Assembly

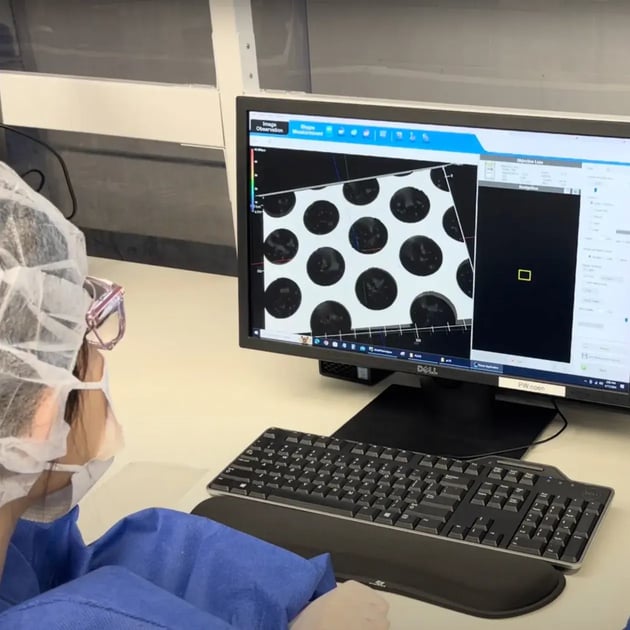

Critical to Function Components: QC Testing

Quality is non-negotiable within the Diagnostic, Medical Device & Optics industries. Edge QC testing for critical to function components includes:

- Pressure, leak, and flow testing

- Wettability and surface energy measurement

- Custom developed test methods to meet your quality inspection needs

Advanced Delivery Options

Proprietary Lidding & Bonding Technologies

Edge utilizes both common and proprietary lidding and bonding technologies to ensure the most cost-effective and robust, pressure-tested solution for customers’ products. We offer a number of bonding technologies, including thermal plastic-to-plastic bonding, laser welding, silane coupling as well as PSA adhesive-based solutions. Our team’s deep knowledge of relevant polymer chemistry is a key factor in our ability to optimize process development and reduce lead times.

Packaging & Labeling

Edge will design packaging and labeling that precisely meet your product requirements. This will ensure proper identification and the safe, particle-free delivery of components and assemblies. Our packaging and labeling solutions are ISO 13485 and CFR 820 compliant.

Fluidic Applications: Bonding and Lidding Technologies

Edge provides comprehensive bonding and lidding technologies for fluidic applications:

.png?width=1200&height=627&name=Edge%20Exclusive%20Tech%20Post%20(1).png)