Injection Molding

Advanced injection molding that enables your next-generation biopharma, medical, or optical technology

With deep focus on biocompatibility, excellent optical performance, and microscale precision, we have more than 3 decades' experience helping leading product companies bring their next-generation technologies to market

- Injection mold presses ranging from 50-ton to 400-ton

- Parts up to 148 mm by 98 mm footprint with 10 mm thickness

- Minimum feature size: 10 µm width & 30 µm depth

- Smaller features available with our compression molding service

- Contiguous services for assembly, lidding, and packaging

- Full inspection suite using confocal microscopy, digital microscopy, spectrophotometry, and more

%20(1).png?width=2048&height=1536&name=zeonbuilding%20(2048%20x%201536%20px)%20(1).png)

Facility details

- Molding, bonding, assembly, and packaging integrated into Class 7 (10,000) clean room

- ISO Certification (9001:2015, 140001:2015, 13485:2016)

- Capacity over 1 million pieces per year

- Molding capabilities established in 1990

.png?width=2048&height=1536&name=zeonbuilding%20(2048%20x%201536%20px).png)

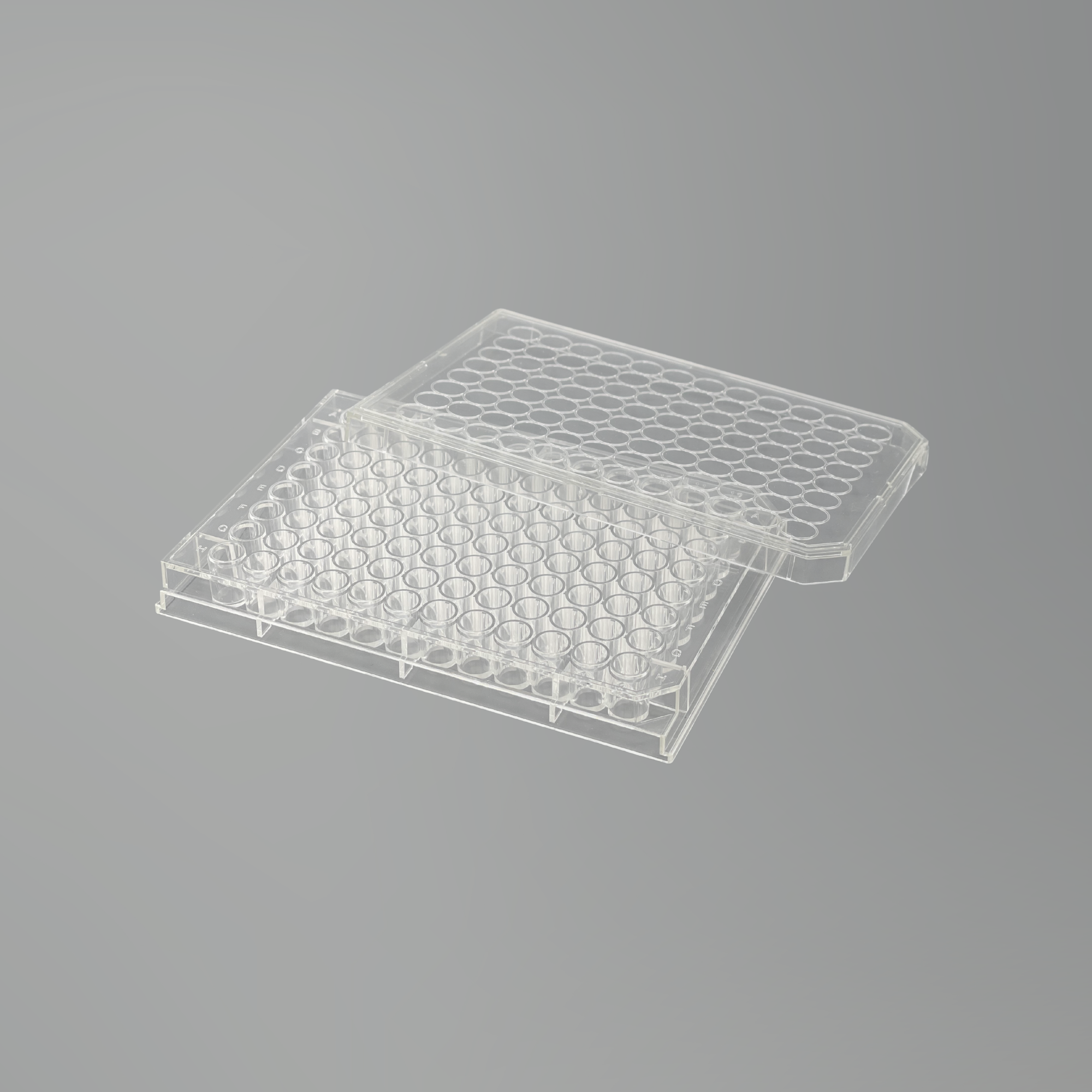

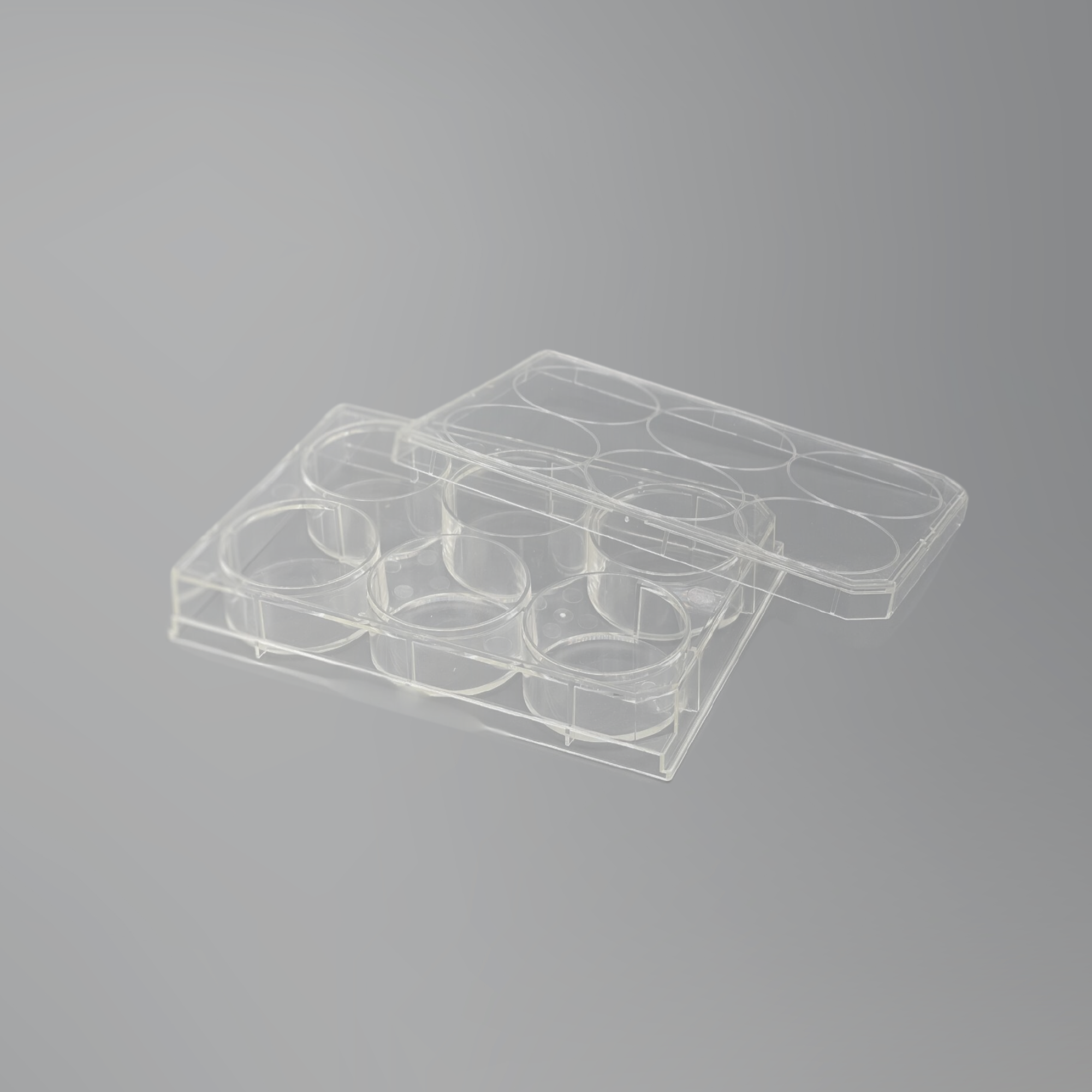

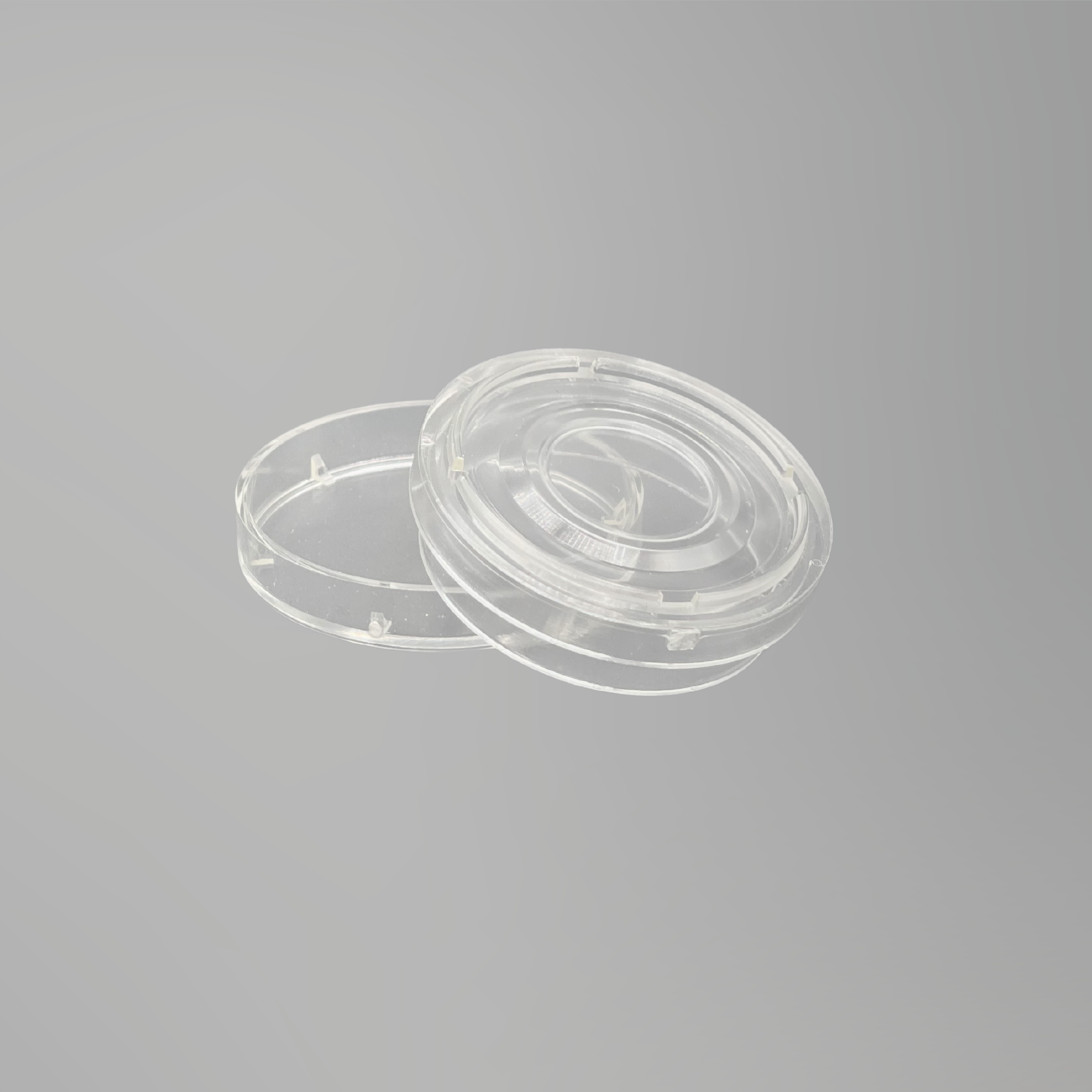

Example products

- Mircoplates, including 6-well, 96-well, 384-well, and more

- Fluidic devices, including lidding and packaging