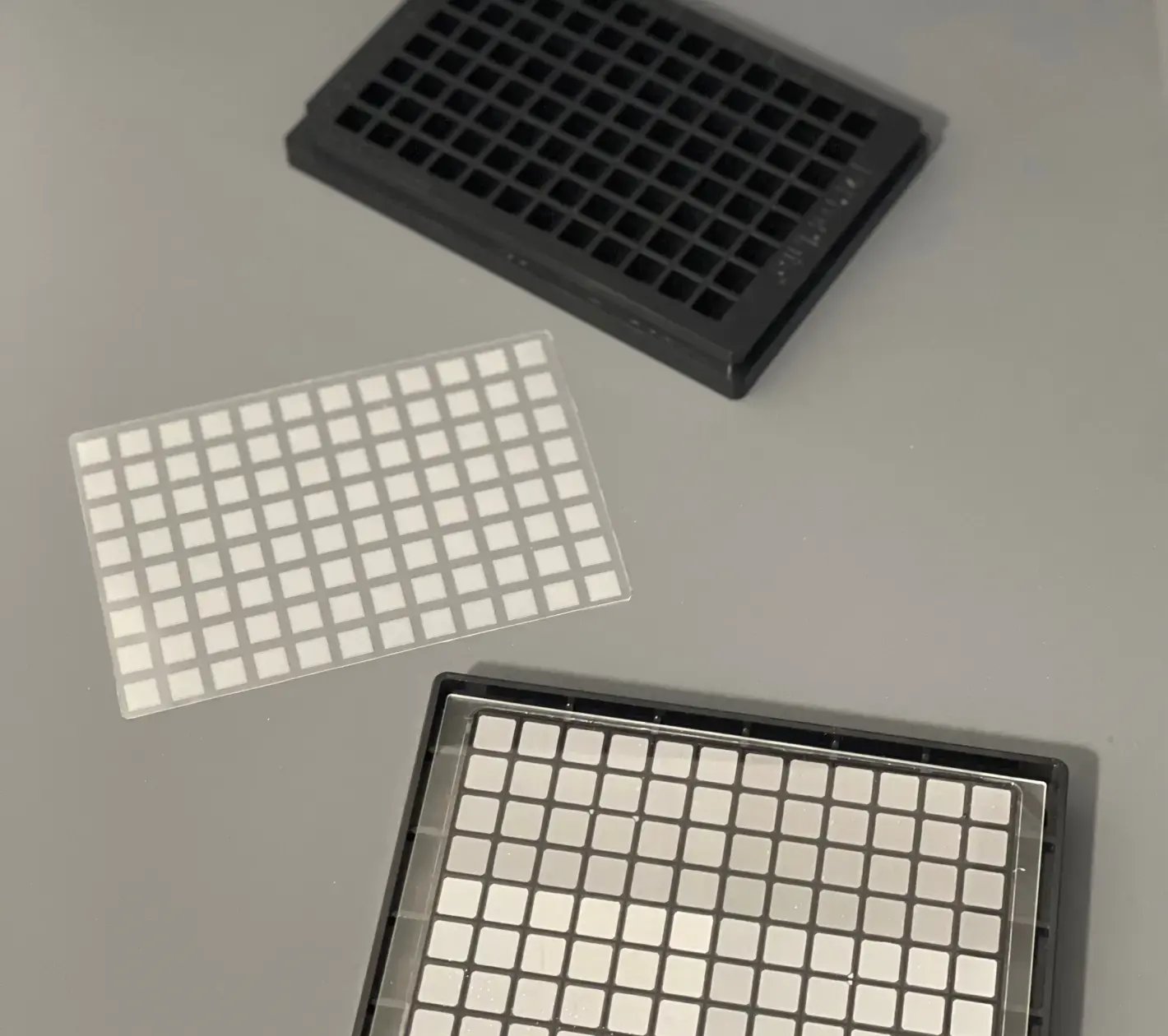

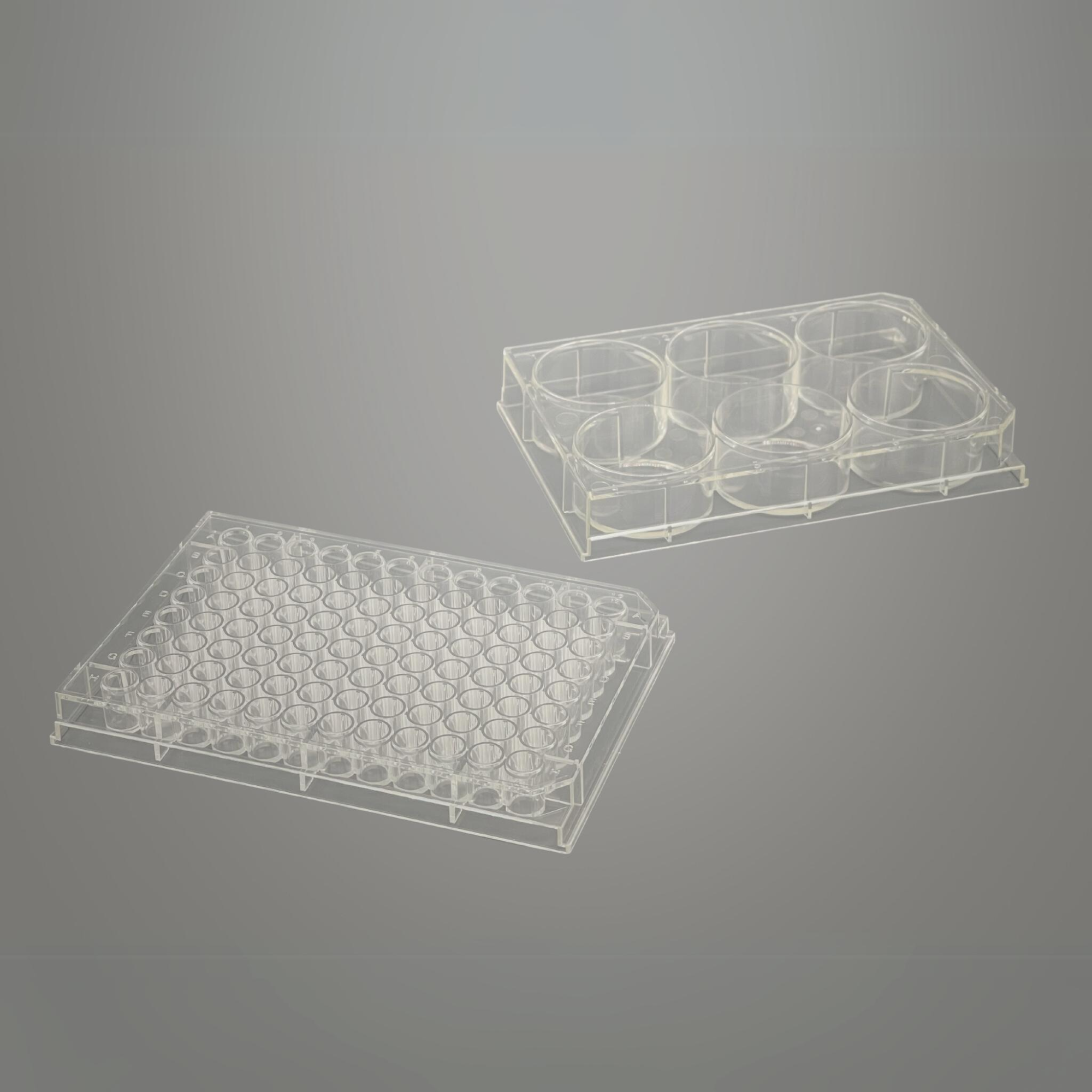

Manufacturing of Plastic Consumables

for Diagnostic, Medical Device & Optics industries

What We Can Do For You

Edge is a full-service plastic consumables manufacturer with the capabilities to take designs with precision microfeatures and tolerances from planning through production, plus handle all aspects of supply chain management.

Edge prides itself on providing the fastest path to market for high-quality products.

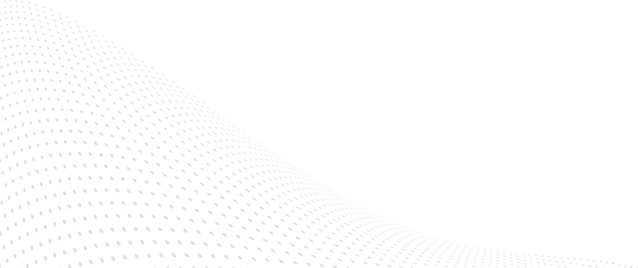

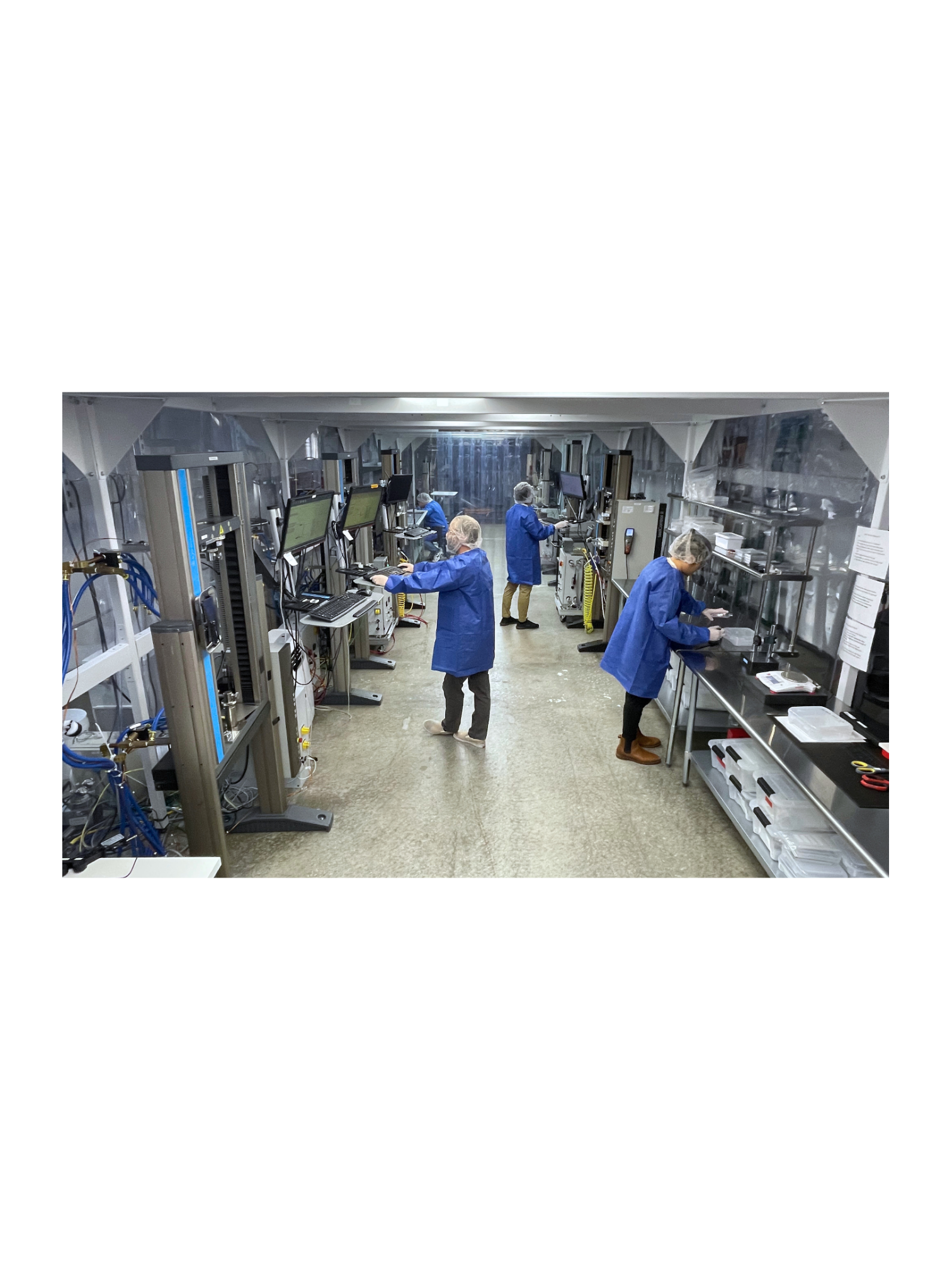

Compression molding 12,000 SQFT / BILLERICA MA

- ISO 13485:2016 COMPLIANT

- CLASS 7 (10,000) CLEAN ROOM

-

CAPACITY OVER 1 MILLION PIECES/YR

-

PROTOTYPES AVAILABLE FROM 1 PIECE

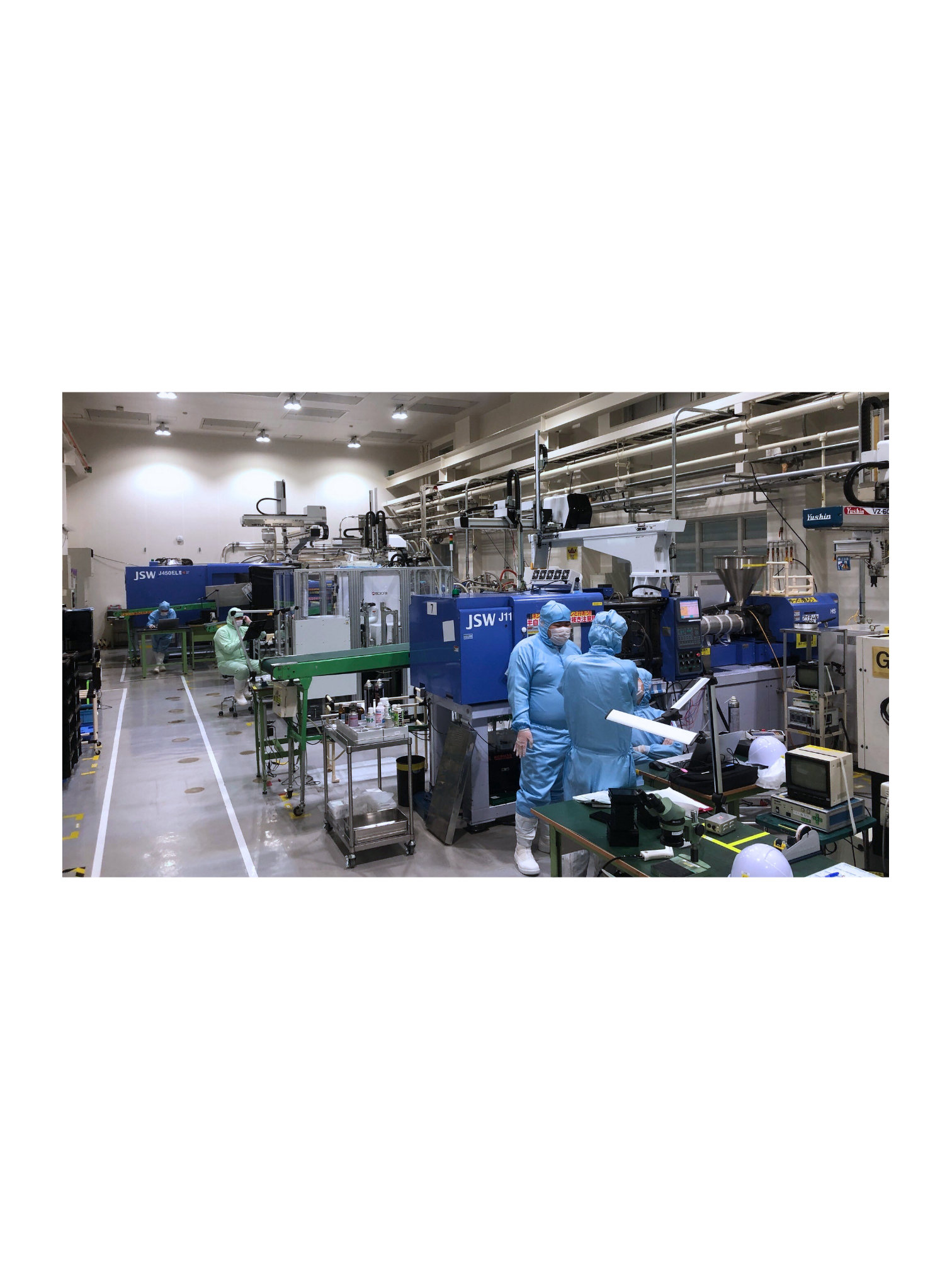

injection molding 48,000 SQFT - SANO JP

- ISO CERTIFIED (9001:2015, 140001:2015, 13485:2016)

- CLASS 7 (10,000) CLEAN ROOM

- CAPACITY OVER 1 MILLION PIECES/YR

- PROTOTYPES AVAILABLE FROM 1 PIECE

The Latest From Edge Precision

ZEON acquires patents for Deterministic Cell Separation technology from GPB Scientific, Inc. ‐ Accelerating cell therapy through innovation

Zeon acquires Deterministic Cell Separation technology patents from GPB Scientific to advance innovation in cell therapy and strengthen its presence in the life sciences field.

%20(2).png)

Edge Precision at MD&M Midwest 2025 – Booth #3912

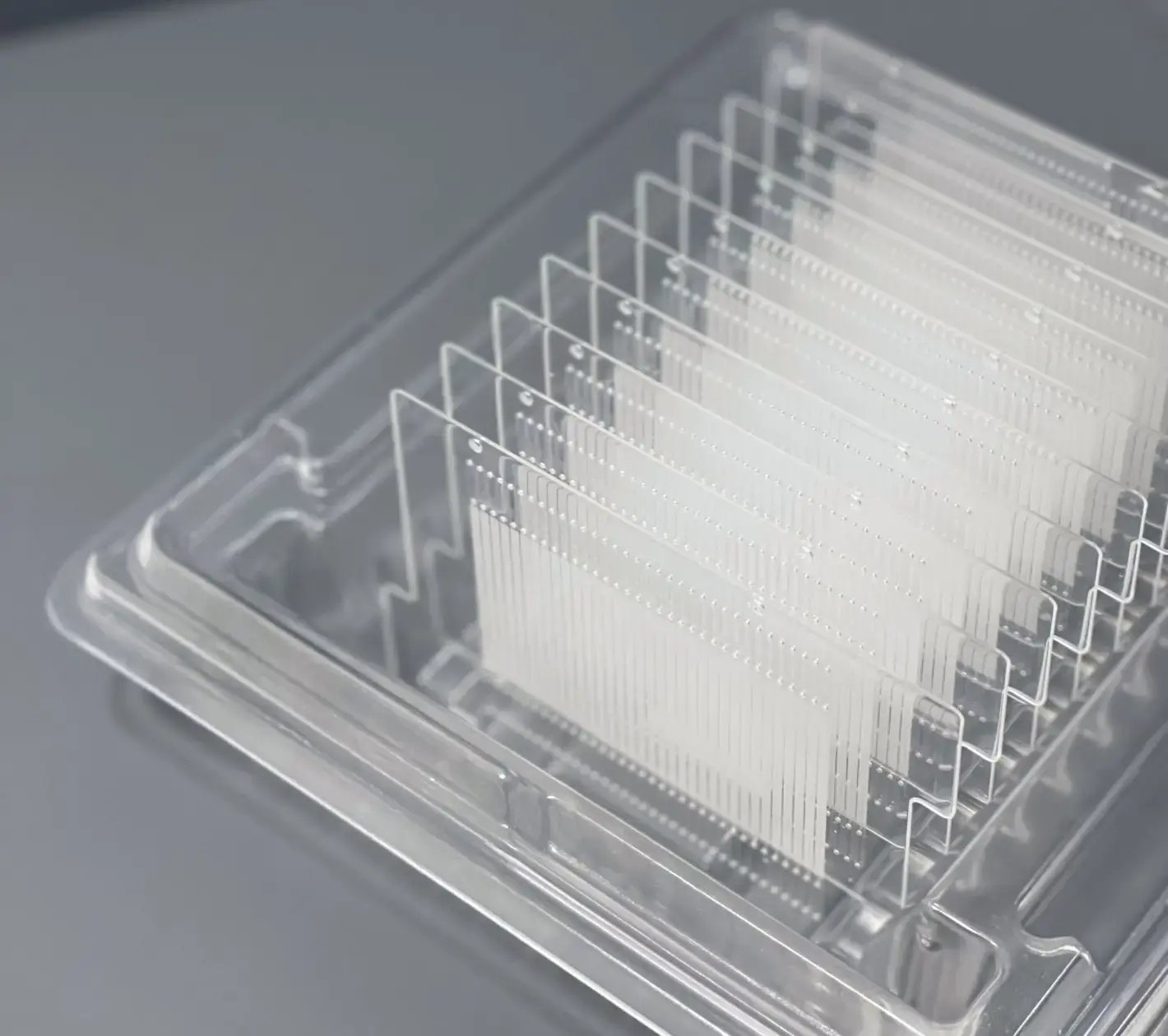

Edge Precision is exhibiting at MD&M Midwest on October 21–22, 2025. Visit Booth #3912 to explore our precision molded COP components, microfluidic plates, and bonded assembly solutions for medical diagnostics.

%20(1)-1.png)

Visit Edge Precision at MEDevice Boston 2025 – Booth #121

Edge Precision is exhibiting at MEDevice Boston 2025 on Sept 30–Oct 1 at Booth #121. Stop by to see custom microplates, microwell slides, and COP-based components built for life science applications.

Additional Capabilities

As a manufacturer of precision consumable parts and assemblies, Edge has an experienced team that provides seamless service and support from design optimization through high-volume production.

Design & DFM Review

Edge’s engineers utilize our manufacturing experience to optimize your design for production scale-up and compliance with product and regulatory requirements.

Assembly

Edge's assembly process integrates robust quality controls, ensuring repeatable product manufacturing. This scalable approach guarantees consistent quality and efficiency throughout production.

Program Management

Edge provides our customers with a fast-paced collaborative experience with a focus on quality and product delivery.

.png?width=152&height=65&name=a%20ZEON%20company%20(3).png)

-1.png?width=152&height=65&name=a%20ZEON%20company%20(4)-1.png)