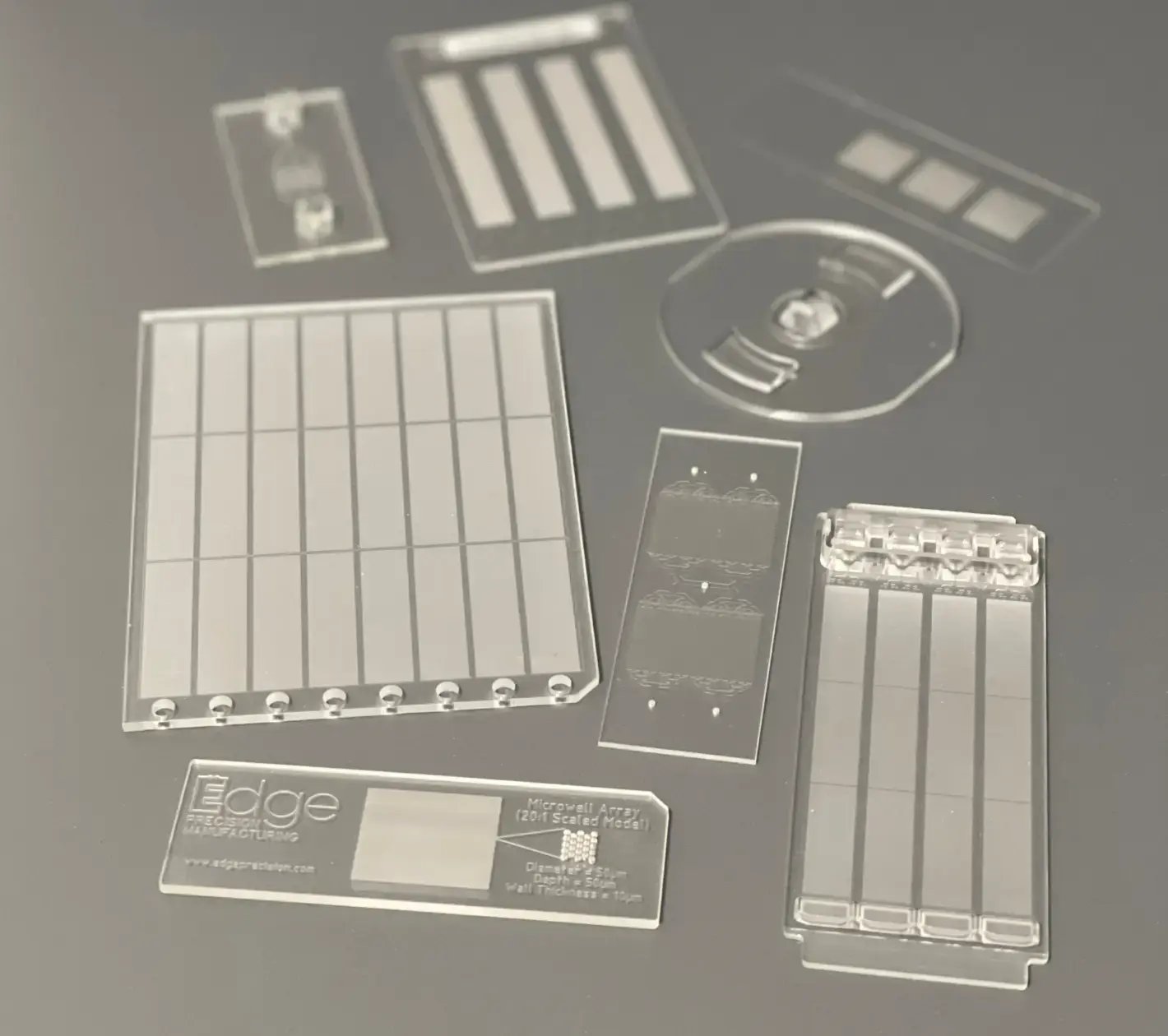

Manufacturing of Plastic Consumables

for Diagnostic, Medical Device & Optics industries

What We Can Do For You

Edge prides itself on precision to provide the fastest path from planning to market.

Diagnostic, medical device & optics applications are often complex and highly regulated. Edge is a full-service plastic consumables manufacturer with the capabilities to take designs with exacting microfeatures and tolerances from planning through production, plus handle all aspects of supply chain management.

- Design input & review

- Material discussion

- Volume & quality requirements

- Assembly planning

- Tool building

- Process development

- Characterization

- Detailed metrology

- Functional testing

- Customer testing

- Design iteration

- Tooling updates

- IQ/QQ

- Process qualification

- Quality agreement

- Product launch

- Volume scale-up

- Quality control

Take The Virtual Tour

Take a look inside of our 9,000-square-foot facility to see what makes Edge the plastic consumables manufacturer of choice for the Diagnostic, Medical Device & Optics industries.

9000 sqft

Manufacturing Facility

ISO 13485

Compliant

Class 7

Clean Room

Capabilities

As a manufacturer of precision consumable parts and assemblies, Edge has an experienced team that provides seamless service and support from design optimization through high-volume production.

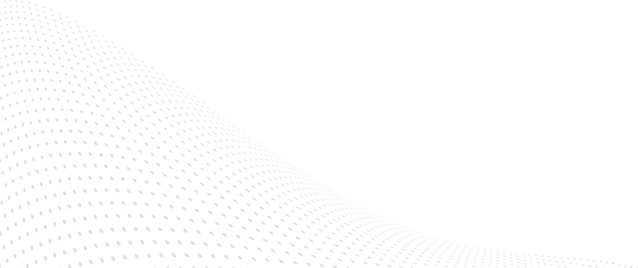

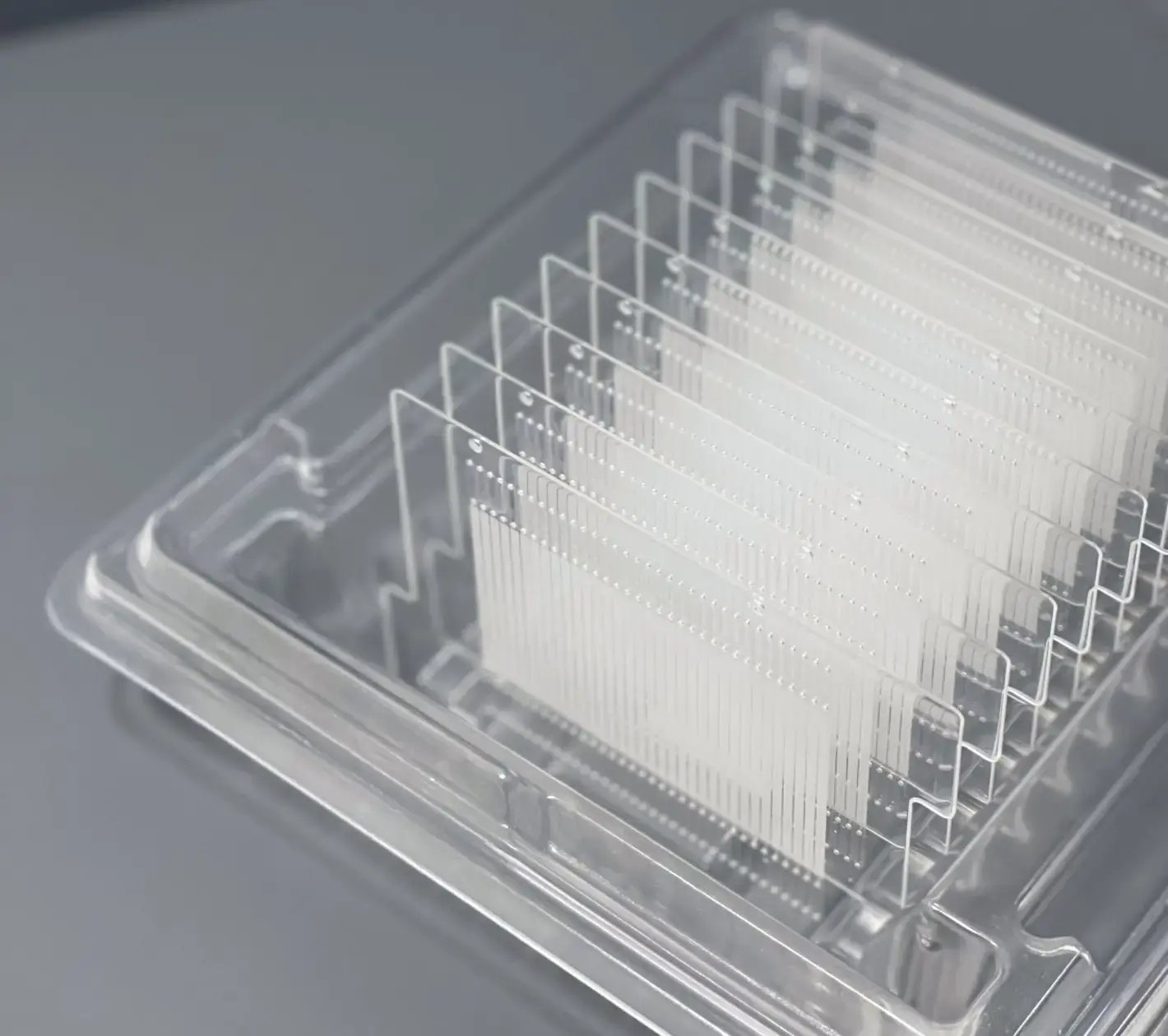

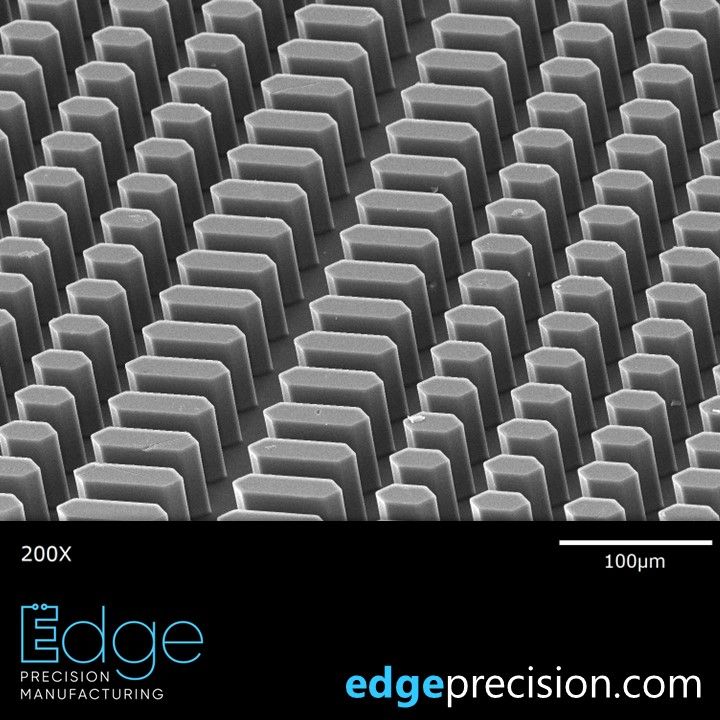

Precision Molding

When your application requires single-digit micron accuracy and assurance of defect-free production, Edge compression molding and injection molding services deliver.

Material Recommendations

Edge's materials experts assist you in finding the right material for your product requirements.

Design & DFM Review

Edge’s engineers utilize our manufacturing experience to optimize your design for production scale-up and compliance with product and regulatory requirements.

Assembly

Edge's assembly process integrates robust quality controls, ensuring repeatable product manufacturing. This scalable approach guarantees consistent quality and efficiency throughout production.

Program Management

Edge provides our customers with a fast-paced collaborative experience with a focus on quality and product delivery.

The Latest From Edge Precision

Is My Application a Good Fit for Edge Proprietary Molding?

Custom consumable parts that offer the precision of micron-scale features at costs similar to injection molded parts, delivered in as little as 6 weeks

Achieving Precision in Blood Cell Separation: The Role of Deterministic Lateral Displacement and Dimensional Stability

Achieve precision in blood cell separation with deterministic lateral displacement and dimensional stability. Learn how Edge's process ensures long-term device performance.

Connect with Edge at BIO 2024: Learn about our advanced solutions

Meet Mario Capolongo at BIO International Convention 2024 in San Diego to discuss Edge's precision manufacturing solutions for your consumable products. Learn more about microfluidics and sealing methods.